FROM STANDARDIZATION TO CUSTOMIZATION

- Serial production of equipment

- Lean manufacturing, efficient organization

- Capacity to design and produce prototypes

- Work teams and installations to carry out large projects

- Full assembly and long run tests of all finished installations at the TAVIL site

- Commissioning and training at client's site according to production planning

Personalized project management

Case study

time line

requirements

office layout

solution

validation

customisation

validation

and setup

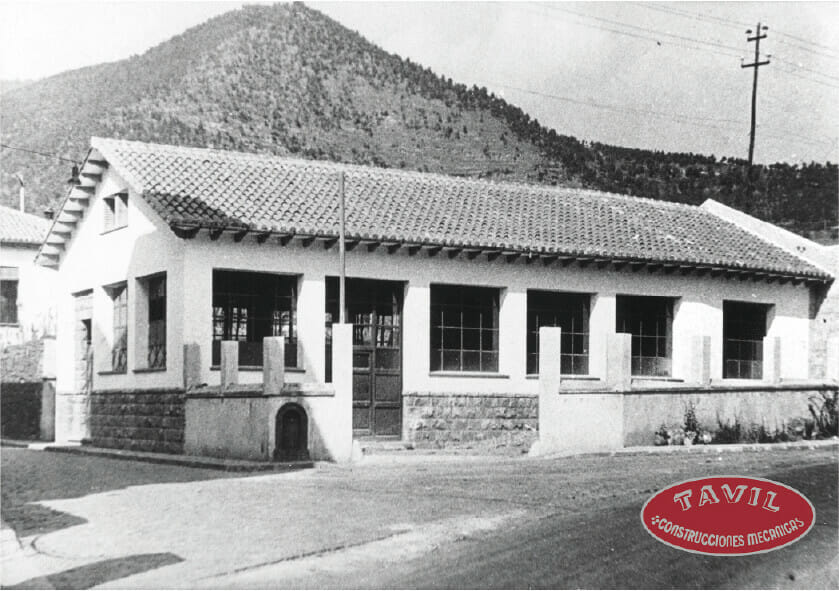

OUR HISTORY

As the industry leader, Tavil offers the best guarantee for improving your production processes by reducing costs and increasing productivity.

TAVIL equipment technology is based on multiformat systems with automatic changeover that can be rapidly adapted to meet the continuous changes of the packaging market requirements.

TAVIL technology continually evolves based on the advances of our R&D+I department and our Industrial and Electronic Engineering department. We also offer a technical support service to meet the needs of each client.

This continual evolution complies with the requisites of the market; TAVIL ensures precise and rapid solutions for our clients.

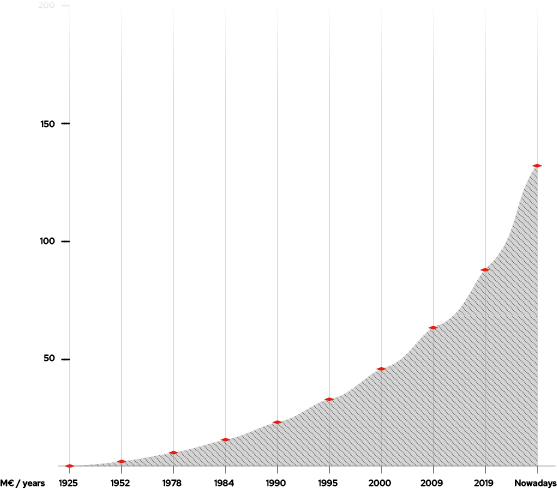

Company Timeline

PRESENT

Consolidation of subsidiaries in various strategic points with in-house engineering teams in important markets such as the United States

2019

New production site of 102,000 m2 with capacity to manufacture the most modern and largest packing and palletizing plants in the world

2009

Development of Max Pallet — the easiest software for adding new formats to palletizing installations

2000

TAVIL became the world leader in innovation in multiformat technology for automatic packing, product loading, and palletizing installations

1995

Consolidated its internationalization with clients worldwide

1990

Development of the fastest Automatic Changeover in packing installations to work with different box dimensions, and expansion into all food and non-food sectors

1984

New 15,000 m2 production site with 50 employees

1978

Development of the automatic tying machine, and specialization in machinery for advanced industrial processing of meat products

1952

Foundation of the company, manufacturer of industrial machinery

Global awareness

Quality

- Focus on quality and long-lasting equipment

- 5S quality management

- FAT and SAT for all projects

- Industry 4.0

- Stainless steel

Safety

- Adaptability to international

safety regulations - Installation audits by certified safety organizations in all countries

- Performance level D

Environment

- Technology designed under smart saving energy criteria

- Green company, environmentally-friendly

- 100% recycling commitment

Partner relationship

Partner relationship

This commitment to excellence enables us to build long-term relationships and form technological partnerships with our clients.

to tavil