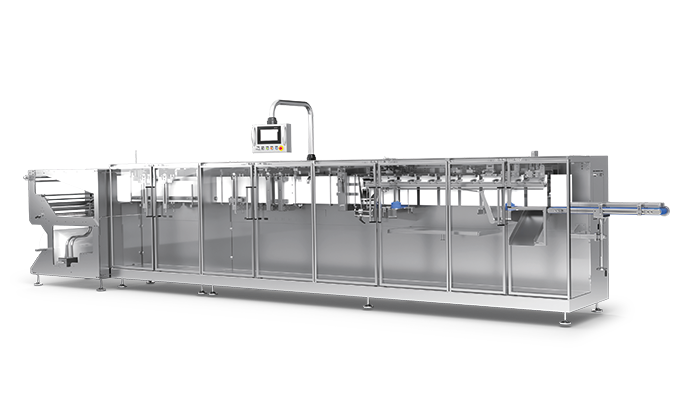

HFFS SERIES

Complete range of flexible packaging solutions from a film reel.

Different flexible applications.

From flat sachets with 3 or 4 side seals to stand-up or gusseted pouches.

Capacity to package a wide range of different products: powder, liquid, cream, granules or solid.

Ability to work with various types of films, including recyclable monomaterial films to meet the latest environmental standards.

STAND UP SERIES

- Range of bags from 50 x 60 mm to 300 x 400 mm.

- Modular machine allowing configurations to meet all possible pouch presentations.

- Simplex, duplex, triplex or quadruplex configurations available.

- Multiple pouch designs available, such as corner or top spout, zipper, straws, full or partial shapes…

- Maximum capacity of up to 1400 cc in duplex and 3000 cc in simplex.

- Wide range of optional equipment such as automatic reel splicers, laminar flow, UV lamps, gas injection, among others.

Stand-up Series Values

| Versatility: Capable of handling a wide range of stand-up and pouch formats and different products on the same machine. | Reliability: Consistent performance under demanding conditions. | Longevity: Capable of operating continuously for long periods of time without failure. |

| Low maintenance: The design minimizes wear and tear and frequent repairs. |

Robustness: The solid main frame and high-quality components provide a robust machine. |

COMPACT SERIES

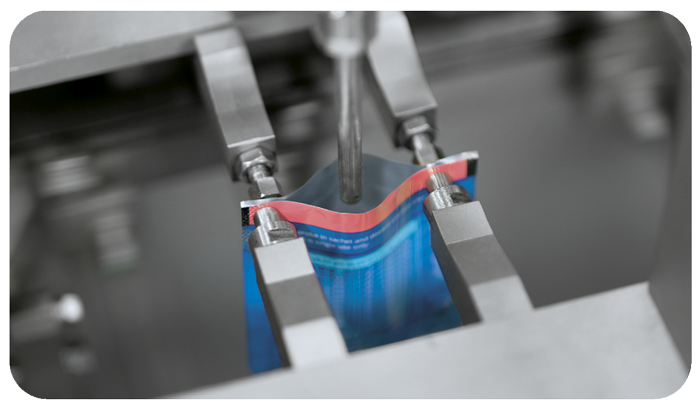

- Medium-sized machine for making 3- or 4-side sealed bags that meets the most demanding market standards.

- Wide range of pouches from 50 x 60 mm up to 220 x 300 mm in Simplex and up to 80 x 300 mm in Quadruplex.

- Capacity to produce up to 90 spm in simplex or 320 spm in quadruplex.

- Simplex, duplex, triplex or quadruplex configurations available.

- Maximum volume capacity of up to 1,600 cc in simplex and 70 cc in quadruplex.

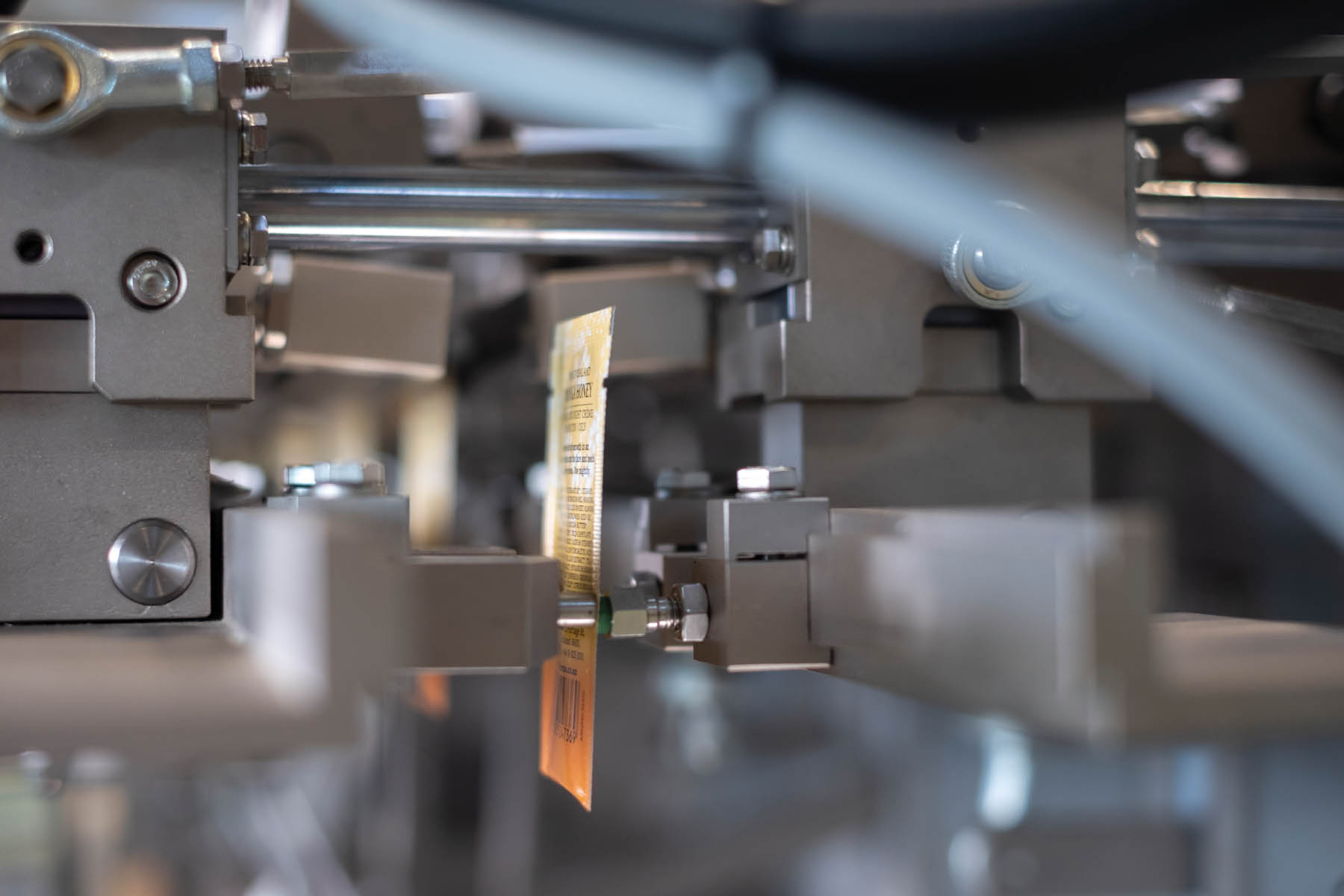

- A wide range of accessories, including date coders, hole punches, bag-shaping dies, zipper applicators, vision control cameras, and pouch applicators, among others.

Compact Cut Values

| Small footprint: Ideal for optimizing space in production facilities while maintaining high operational efficiency. | Reduced maintenance: Thanks to its compact and simplified design, the machine experiences less wear and requires less maintenance. | Reliability: Consistent performance under demanding conditions. |

| Versatility: It can work with a wide range of formats, as well as with different accessories. |

Structural strength: Frame and components made with high-quality materials. |

FINAL CUT SERIES

- Small and compact machine that stands out for its versatility, high efficiency and competitive cost.

- Designed to manufacture envelopes with 3 or 4 side welds and suitable for single, double or chain envelopes.

- Envelope size range from 30 x 30 mm to 130 x 130 mm and up to 65 + 65 x 130 mm in duplex operations.

- Capacity to produce up to 100spm in simplex or 200spm in duplex.

- Maximum volume capacity of up to 60cc in simplex and 20cc in duplex.

- A wide range of accessories such as date coders, hole punches, wet wipes, vision control cameras, etc.

Valores Final Cut

| Small footprint: The machine is designed with a minimal footprint, making it ideal for spaces where saving space is a priority. | Durable Construction: Constructed with robust materials and heavy-duty mechanical components, ensuring long-lasting performance under continuous use. | Cost-effective: Its basic, mechanical design makes it a more affordable option for companies looking for reliable packaging without advanced automation. |

| Simple mechanical operation: The machine is based on simple mechanical components, making it easy to operate and maintain. |

Durable Construction: Constructed with robust materials and heavy-duty mechanical components, ensuring long-lasting performance under continuous use. |

Efficient operation: The machine maintains a high production speed, ensuring the sealing quality of the envelopes. |

RETURN TO MULTIFORMAT PACKING SOLUTIONS