Success Story: How TAVIL Automation Boosted Efficiency at Le&Co

Le&Co, one of the largest producers of ham and meat specialties in the Czech Republic, set out to achieve three key goals: optimize production, improve quality, and reduce operational costs in order to stay ahead in an increasingly competitive market.

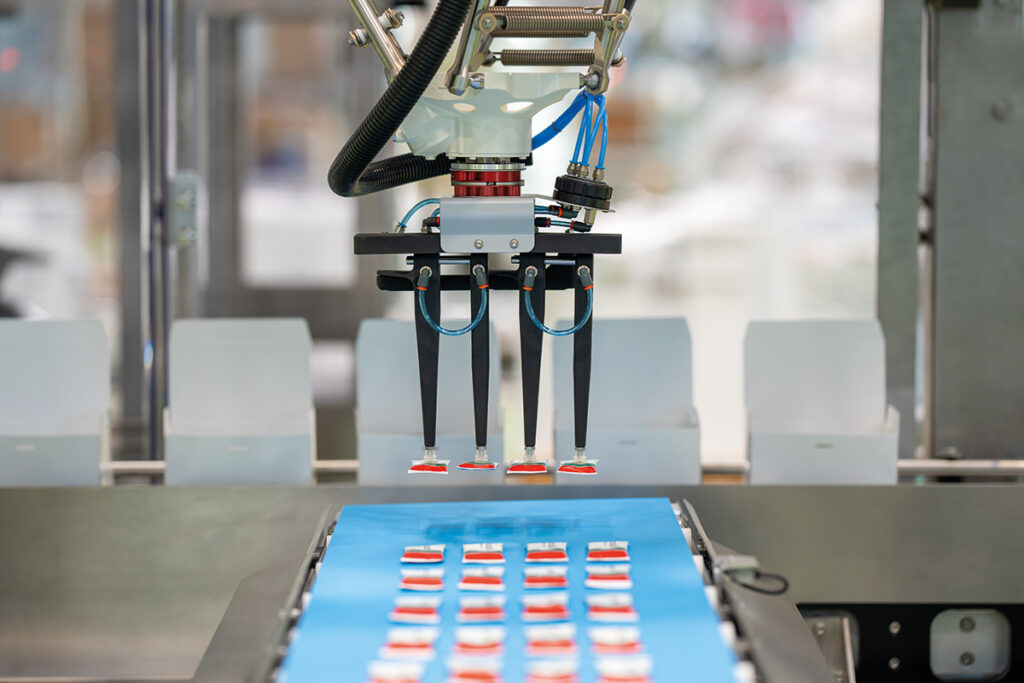

To achieve this, the company partnered with TAVIL to automate its end-of-line process. The result was a fully integrated robotized packing and palletizing system, specifically tailored to their production needs.

The solution delivered remarkable results:

- Replaced manual labor with a fully automated, efficient process.

- Achieved an overall efficiency increase of nearly 60%.

- Enabled the entire line to be managed by just one operator.

- Ensured a faster, more competitive and precise production flow.

Beyond productivity, this transformation marked a key step in Le&Co’s journey towards a more modern, data-driven factory environment.

In the food industry, automation is essential to meet demand, maintain high quality standards, and ensure product safety and traceability.

Watch the video to see how TAVIL helped drive this transformation at Le&Co.